Why A Continuous Waste Pyrolysis Plant Is So Popular

A very popular investment that people are making, one that is going to cater to those that are environmentally oriented, is to invest in a continuous style pyrolysis plant for waste. This is a factory of sorts that is able to take plastic that has been discarded into a landfill, or even rubber tires, and create marketable products as the end result. All over the world, millions of plastic water bottles are being discarded, ending up in landfills, and huge mounds of tires that can sometimes be seen from space are getting even larger with each passing decade. By taking advantage of this thermochemical process called waste pyrolysis, not only can it diminish the amount of waste that is going into landfills, but it will also help shrink the enormous volume of used vehicle tires that are piling up continuously. Here are a few reasons why a continuous waste pyrolysis plant from pyrolysis machine manufacturer has become so popular as an investment for those that have money that are environmentally oriented.

How The Pyrolysis Process Works

This process is actually very simplistic, requiring an apparatus in which very small processed pieces of plastic or rubber can be delivered. Once it has gone into the machine, the oxygen will be removed and that she will be increased between 500 and 550 degrees Fahrenheit. At this point, the thermochemical process will begin and byproducts will be created. This includes charcoal or char, bio oil and syngas, all of which can be sold for a substantial profit to farmers, tire makers, and those that sell diesel fuel from plastic just to name a few. It is also possible to sell this to companies that specialize in cosmetic products, specifically those that are designed to prevent stretch marks. Now let’s look at why a continuous waste pyrolysis plant is recommended above all of the others that you could purchase and use today. And this process is same to batch pyrolysis machine for sale, which output is less than continuous machine. Or please visit our website: https://kingtigergroup.com/continuous-pyrolysis-plant/ to learn more about pyrolysis process.

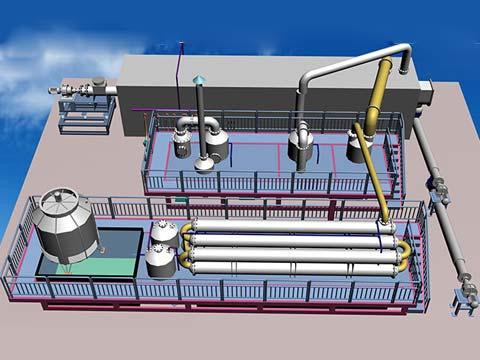

Continuous Waste Pyrolysis Plant Overview

This factory is simply a large pyrolysis plant that has what is called an automatic feeding system. There are also two sealed discharging systems, allowing the end products to be efficiently taken out. Some of the more efficient factories can do up to 50 tons of plastic every single day. Best of all, this can occur 24 hours a day, without needing any human intervention, as far as delivering the plastic into the system. The plastic must first go through some type of waste plastic dryer that can break it down into smaller sizes, and the same is true if you are using this to process rubber from tires. You will end up with a minimum of two different products including bio-oil and carbon black, each of which can be used for a multitude of purposes.

Once you have the factory running, preferably adjacent to a location where millions of tons of plastic have been deposited and are ready to use, you can sell the black char to companies such as iron and steel industries, and also companies that are involved with hotels, restaurants, ceramics, and even in the generation of electricity. The plastic oil can be sold as an alternative type of fuel, specifically for machines that use diesel. This product is also available at local stores, as mentioned before, for stretch marks, and therefore you have an enormous multi-billion-dollar industry looking for this type of oil that is made possible using continuous waste pyrolysis machines for sale. If you want to learn more waste treatment plant, please contact us.