Intelligent Control Systems for Efficiency Optimization

The integration of advanced control systems is redefining the operational landscape of the charcoal production machine. Automation platforms now include programmable logic controllers (PLCs) coupled with human-machine interfaces (HMIs), enabling real-time monitoring and process optimization. Parameters such as carbonization temperature, biomass feed rate, and gas flow are precisely regulated, ensuring consistent quality across different input materials, including wood chips, coffee husk, and bamboo.

Automation not only reduces manual intervention but also minimizes the margin for error, especially in large-scale production environments. This is particularly beneficial for operators of wood charcoal manufacturing machine systems, where feedstock heterogeneity can significantly affect carbon yield and energy balance.

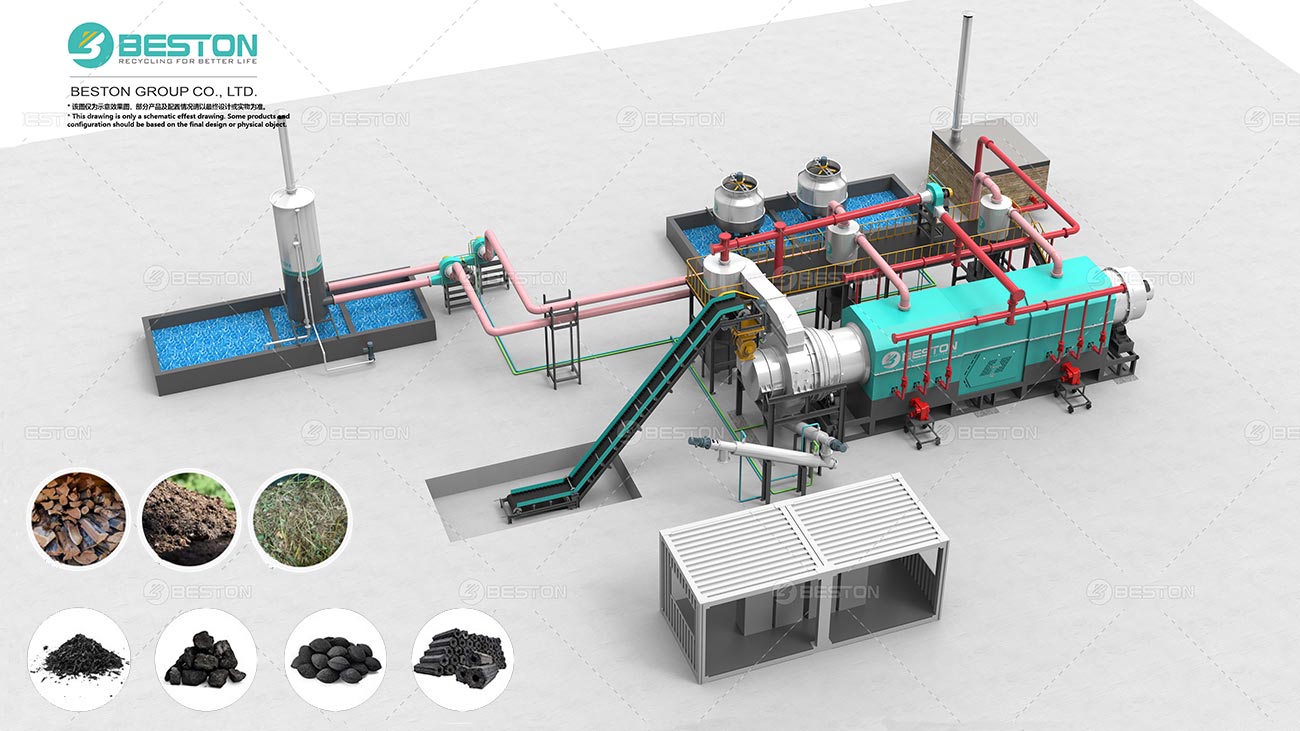

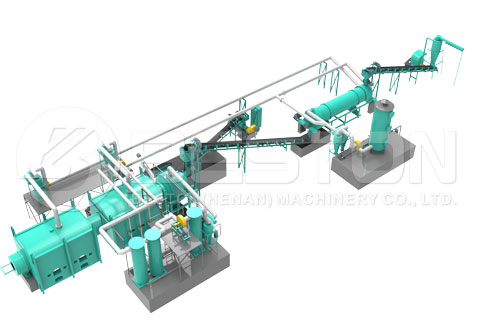

Modular Design and Adaptive Feeding Mechanisms

Modern wood charcoal manufacturing machine is increasingly being built with modular components. These modules can be reconfigured or scaled depending on production demand, space availability, or feedstock type. Automated feeding systems, often equipped with intelligent sensors, adapt to the moisture content and particle size of raw materials. This advancement allows seamless operation even with irregular biomass inputs such as coconut shells or sawdust.

Adaptive feeders also reduce clogs and thermal inefficiencies, improving energy utilization across the system. In particular, coffee husk charcoal making machine models benefit from this automation, as the lightweight and volatile nature of the feedstock requires precise handling to avoid combustion loss.

Remote Monitoring and Predictive Maintenance

Cloud-based diagnostics and IoT-enabled sensors are becoming standard in high-end charcoal production machine configurations. These systems allow remote access to performance metrics, operational history, and predictive maintenance alerts. Through machine learning algorithms, data is analyzed to predict wear patterns, optimize energy input, and reduce downtime.

This trend is especially impactful for distributed operations or contract manufacturing facilities producing BBQ or shisha-grade charcoal. By leveraging remote diagnostics, operators can manage multiple units from centralized dashboards, reducing personnel requirements and enhancing uptime.

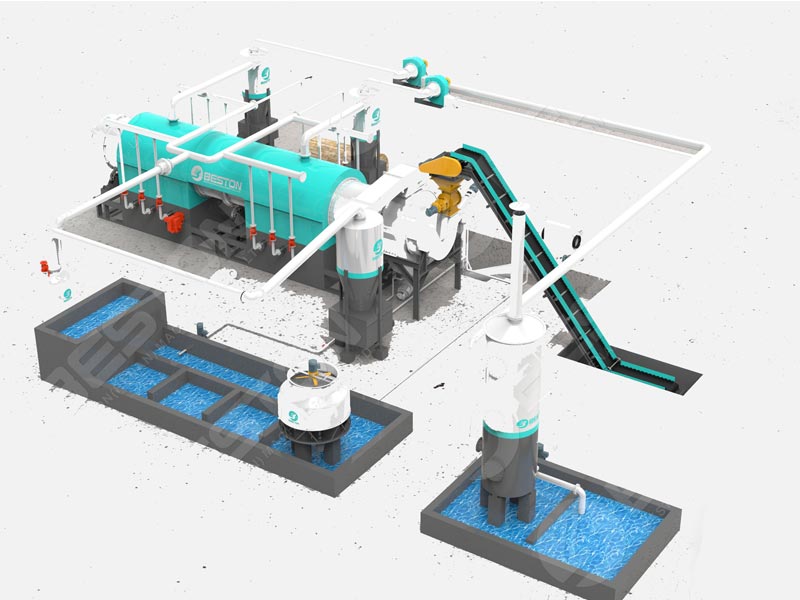

Automated Emission Control Systems

Environmental compliance is a growing concern in the carbonization sector. Charcoal production processes emit volatile organic compounds and particulates, especially during the initial drying and pyrolysis stages. New-generation charcoal machines incorporate automated flue gas treatment systems, including cyclones, wet scrubbers, and activated carbon filters.

Emission control is fully integrated into the machine’s control architecture, allowing continuous adjustment based on emission load and operating temperature. This is particularly relevant for operators using wood charcoal manufacturing machine or coffee husk charcoal making machine systems in regions with stringent air quality regulations.

Energy Recovery and System Integration

Automation also facilitates energy recovery from pyrolysis gases. Waste heat from the reactor chamber is repurposed to dry incoming biomass or generate steam for ancillary operations. This closed-loop system reduces external energy dependence and increases overall process efficiency.

Integrated automation ensures synchronization between all subsystems—from biomass input to carbon output and heat recovery—maximizing the thermodynamic efficiency of the plant. For charcoal producers targeting high-grade applications, such as the BBQ charcoal making machine sector, this level of automation translates into consistent quality and reduced operational expenditure.

Conclusion

The latest trends in charcoal machine automation center around intelligent control, adaptive operation, and environmental performance. Whether in a small-scale coffee husk charcoal making machine or an industrial wood charcoal manufacturing machine, automation is reshaping the efficiency, scalability, and sustainability of charcoal production. These innovations support precision manufacturing while aligning with global trends in clean energy and circular resource utilization.