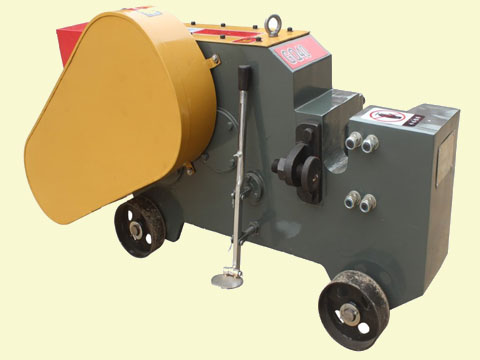

Twisted wrought iron can be a beautiful decorative element for fences, railings, and countless other applications. As you can well imagine, it takes a tremendous amount of strength to physically twist wrought iron. In order to have enough power to cause the metal to twist evenly, you need to use a wrought iron twisting machine. These machines are specifically designed to create twisted lengths of wrought iron, making them an invaluable tool to have in your shop if you create a lot of this type of ironwork.

In terms of how to go about buying one of metal craft twisting machines, there are a couple different approaches that you can take. First, you can try going directly to a manufacturer to purchase your machine. To find companies that manufacture twisting machines, try searching in your favorite search engine. Several different manufacturers should come up. Write down the contact information for each company. Give them a call to find out whether or not they have a catalog that you can view or whether they can share information about the machines that they have available. Be sure to inquire about pricing as well as the overall functionality of the machines. Ellsen offers better functional and appropriate price for you. Click here http://ellsenwroughtironmachine.com/ to know detail!

Don’t forget to read reviews of these companies like Ellsen so that you know whether or not they produce high-quality machinery. After all, these machines can be somewhat expensive. Before you invest your money, it is important to know that you are getting a piece of equipment that is built to last. This will help ensure that you get the most benefit out of your investment.

Another option is to look for used machines. Sometimes, companies go out of business or change their product lines. When this happens, they often liquidate their old equipment. This can be a fantastic way to find a bargain on one of these machines. If you do happen to find one for sale, make sure to carefully check its technical specifications before purchasing it. Otherwise, you run the risk of buying a machine that won’t work for your needs.

If possible, you should also inspect the machine in person to make sure that everything is in good working order. Ask the seller to demonstrate how it works so that you can see that it functions the way it was intended to. Be wary of any sellers who are not willing to show you how the machine works. It could be a sign that it is broken or experiencing other types of problems.

Buying a wrought iron twist bend machine isn’t something that most people do every day. However, the process is not much different than buying any other piece of equipment. Before you invest your money, you should always do research to make sure that you are buying a high-quality twisting machine http://ellsenwroughtironmachine.com/wrought-iron-twisting-machine/ that will last for a number of years. As with any major purchase, the more time and effort you put into finding the right product, the happier you will be with your results.