There is often a lot of confusion when it comes to operating a winch, let alone industrial winches. Part of this confusion has to do with not understanding the difference between a hoist and a winch. They look very similar, but they are made for completely different purposes. Once you understand the differences between these two very necessary devices used for lifting heavy items, you can then understand how the mechanisms work. Let’s look at the differences between hoists and winches, and then show you how to operate most of the industrial winches that are available today.

What Is A Winch?

A winch is simply a device that can lift heavy loads over either a level surface, or an inclined surface, and it will do so horizontally. A hoist winch does exactly the same thing, but it is used to lift things vertically. For example, if the angle of ascent is more than 45? a hoist is going to be used. Either one of these can lift several tons each, and depending upon how they are made, they can either be very easy or difficult to operate.

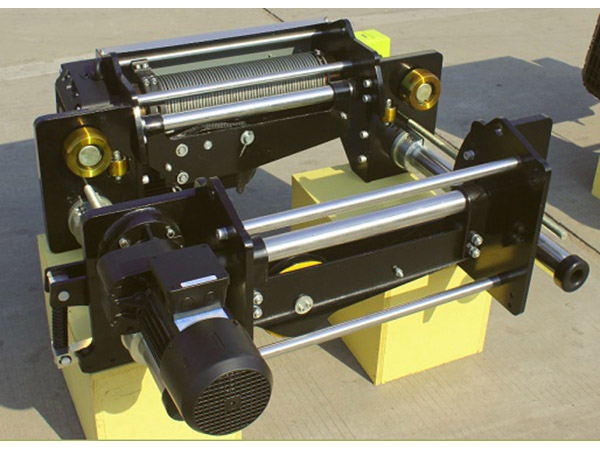

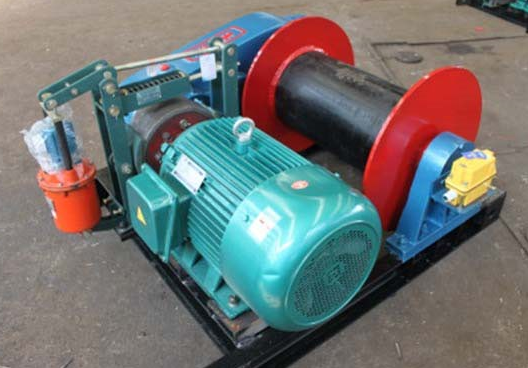

How A Winch Actually Works

These devices use a rope or cable that can put a considerable amount of tension between the winch and the object that is to be moved. The drum on a winch can be operated either manually, or through the use of electricity, air or hydraulics. Those that are able to lift hundreds of tons typically use hydraulics because of the power that these mechanisms can provide. However, if you are working a pulled winch, there is going to be a rope that goes around the barrel or drum which will then be pulled by individuals. This basic mechanism works the same for either manual or automated winches. Now let’s look at how to operate most of the industry winches that are produced today.

How To Operate An Industrial Winch

You can operate these, if they are electricity winches, using switches or levers that are built into the actual apparatus. By moving the lever up or down, or backwards or forwards, it will engage the electric mechanism. The same is true for industrial winches which are typically hooked up to either some type of air compression device or hydraulics. Essentially, they work in exactly the same way you would operate in manual winch with the exception that the motor and the hydraulics are doing all of the work for you.

Each industrial Winch that you will come across to will operate completely differently. You simply have to find one that is easy to use. You can look at reviews on the Internet for the different winches that are sold, and also find videos created by people that actually own and operate industrial winches of their own. After you have found one that looks very simplistic, yet can lift the amount of weight that you needed to, you can order one of these to start enjoying how easy it will be to move your merchandise in your factory or warehouse using these basic controls. want a winch? click https://ellsenwinches.com/industrial-winch/ or to visit our site: www.ellsenwinchmanufacturer.com.