Oil sludge is formed when oil contaminates with water and solid residues during oil processing process or in the car engines. Oil sludge causes more harm when released directly to the environment but can be recycled to a high value product. Pyrolysis plant offers efficient and cheap alternative to recycling oil sludge compared to other recycling alternatives. The end products of sludge oil treatment are of a significant economic value thus making the project worth the investment. Individual clients can chose to customize the pyrolysis plant in order to suit their industrial capacity and operation control. We are going to discuss benefits of using the oil sludge treatment plant to treat oil sludge.

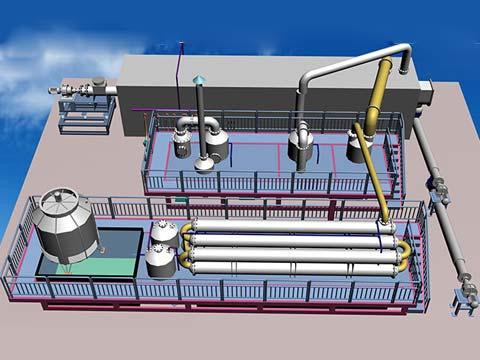

How oil sludge is treated using pyrolysis plant for sale

The aim of this process is to separate oil sludge into original constituents which include water, solid residue and oil. The contaminated oil is fed into the combustion chamber and subjected to high temperature in absence of air. Due to different boiling points, different materials contained in the oil sludge will begin evaporating. The vapour is then tapped and cooled down in order to obtain different end products. Waste water can be recycled though water treatment plant while gas and oil can be used in engines and as source of energy.

Benefits of using the pyrolysis plant to treat oil sludge

Environmental friendly

The oil sludge process equipment helps in environment conservation since it eliminates direct release of the oil sludge to the environment. If exposed to the environment, the contaminated oil will flow its way to water bodies. This will endanger animal species found in the water bodies by cutting short oxygen supply. People benefiting from the water bodies for irrigation and domestic purposes will also be affected by the contamination. Pyrolysis treatment thus helps in protecting aquatic life and human life as well.

Quality oil is produced

The quality of oil produced from the treatment is just good like crude oil. This means that it can be used in running engines without the fear of causing mechanical damage or failure to the engines. This will benefit the organization since it subsidises the cost of fuelling engines. You can also use the waste oil to diesel machine to refine the oil. Get the pyrolysis machine price 2020.

Cost effective

Compared to other alternatives of disposing oil sludge like burning, pyrolysis is cheap and produces by-products that are of economic value. Gas produced can be used as a source of fuel while oil can be used in industrial engines thus saving the running costs. This means that the benefit of acquiring the plant outweighs the investment cost over the long run. The running and maintenance cost of the plant is low since emitted gas is recycled to fuel the plant. There is low risk in running the plant since oxygen is not used in combustion.

Pyrolysis plant can be used for alternative purposes

Apart from recycling oil sludge, pyrolysis plant can be used to recycle plastic and rubber wastes to useful oil, gas and coal. This is important especially in the case where oil processing is seasonal or is done in small scale: https://www.bestongroup.com/small-pyrolysis-machine/. The ability to recycle different waste products makes pyrolysis plant investment worth the risk since the plant still remains relevant even when there is change in the processing plan.