Continuous pyrolysis, an innovative and evolving technology, has emerged as a potential game-changer in addressing climate change by providing a sustainable approach to waste management and renewable energy production. In this in-depth 3077-word post, we will explore the principles of continuous pyrolysis machine, its role in mitigating climate change, environmental benefits, challenges, and the broader implications for a sustainable future.

Introduction to Continuous Pyrolysis:

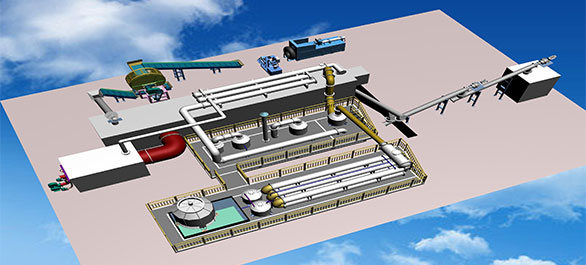

Continuous pyrolysis is an advanced thermal decomposition process that involves the conversion of organic materials into valuable products such as biochar, bio-oil, and syngas. Unlike traditional batch pyrolysis, which operates intermittently, continuous pyrolysis systems enable a continuous and uninterrupted flow of feedstock through the reactor, enhancing efficiency and scalability.

Principles of Continuous Pyrolysis:

Feedstock Selection:

Continuous pyrolysis can utilize a diverse range of feedstocks, including biomass, agricultural residues, municipal solid waste, and plastic waste. The choice of feedstock influences the composition of the end products and the overall efficiency of the process.

Preparation and Feeding:

Prior to entering the pyrolysis reactor, the feedstock undergoes size reduction and drying. This preparation enhances the efficiency of the pyrolysis process. The prepared feedstock is continuously fed into the reactor, ensuring a consistent flow.

Pyrolysis Reactor:

The heart of the continuous pyrolysis system is the reactor, where the feedstock is subjected to high temperatures in the absence of oxygen. This controlled environment facilitates the thermal decomposition of organic materials, leading to the production of biochar, bio-oil, and syngas. The mobile pyrolysis plant has small capacity.

Product Separation and Collection:

The products generated during pyrolysis—biochar, bio-oil, and syngas—are continuously separated and collected. Various techniques such as condensation, filtration, and cyclones are employed to capture and recover each product.

Residue Handling:

The residual char left after pyrolysis, known as biochar, can be utilized as a soil amendment to enhance soil fertility and carbon sequestration. Proper handling and utilization of biochar contribute to the overall sustainability of the continuous pyrolysis process.

Continuous Pyrolysis and Climate Change Mitigation:

Carbon Sequestration:

Continuous pyrolysis contributes to carbon sequestration by converting organic materials into biochar, a stable form of carbon. When applied to soil, biochar enhances carbon storage, mitigating the release of carbon dioxide into the atmosphere.

Renewable Energy Production:

The syngas produced during continuous pyrolysis can be utilized as a renewable energy source. Syngas is rich in hydrogen and carbon monoxide, which can be used for heat and power generation, reducing reliance on fossil fuels and lowering greenhouse gas emissions.

Waste Diversion and Reduction:

Continuous pyrolysis provides an effective solution for waste diversion and reduction. By processing diverse feedstocks, including plastic waste and agricultural residues, the technology minimizes the environmental impact of landfills and incineration.

Bio-Oil Applications:

The bio-oil obtained from continuous pyrolysis can serve as a sustainable alternative to conventional fossil fuels. It can be further refined and used for various applications, including transportation fuels, reducing the carbon footprint associated with traditional petroleum-based products.

Land Rehabilitation and Biodiversity Conservation:

The application of biochar to soil not only enhances its fertility but also contributes to land rehabilitation. Improved soil conditions support plant growth and biodiversity, creating a positive impact on ecosystems affected by climate change.

Environmental Benefits of Continuous Pyrolysis:

Air Quality Improvement:

Continuous pyrolysis operates in a controlled environment, minimizing the release of pollutants and harmful emissions. This contributes to improved air quality compared to traditional waste incineration methods.

Reduced Methane Emissions:

Organic waste decomposition in landfills produces methane, a potent greenhouse gas. Continuous pyrolysis diverts organic waste from landfills, reducing methane emissions and mitigating its impact on climate change.

Resource Recovery and Circular Economy:

Continuous pyrolysis supports resource recovery by transforming waste materials into valuable products. This aligns with the principles of a circular economy, where resources are reused, recycled, and repurposed to minimize waste generation.

Water Conservation:

Traditional wastewater treatment processes associated with certain waste disposal methods can contribute to water pollution. Continuous pyrolysis, by reducing the need for such processes, helps conserve water resources and protects aquatic ecosystems.

Challenges and Considerations:

Technological Complexity:

Continuous pyrolysis systems are technologically complex, requiring sophisticated engineering and control mechanisms. Research and development efforts are ongoing to optimize these systems for efficiency and cost-effectiveness.

Feedstock Quality and Composition:

The quality and composition of the feedstock significantly impact the performance of continuous pyrolysis. Variability in feedstock properties can pose challenges in maintaining consistent process conditions.

Energy Input and Efficiency:

Continuous pyrolysis requires energy input for heating the reactor and maintaining optimal process conditions. Achieving a balance between energy input and the energy value of the end products is essential for the economic viability of the technology. The technology and quality affect the cost. View the thermal desorption unit price.

Market Development:

The market for biochar, bio-oil, and syngas is still evolving. Continued market development and the establishment of clear standards are necessary to create a sustainable economic model for continuous pyrolysis.

Global Implications and Future Outlook:

International Collaboration:

The adoption of continuous pyrolysis has global implications, especially in regions grappling with waste management challenges and the impacts of climate change. International collaboration and knowledge sharing can accelerate the deployment of this technology.

Policy Support:

Governments and regulatory bodies play a crucial role in supporting the development and implementation of continuous pyrolysis. Policy frameworks that incentivize sustainable waste management and renewable energy production can drive widespread adoption.

Integration with Existing Systems:

Integrating continuous pyrolysis into existing waste management and energy systems requires strategic planning. Compatibility with established infrastructure and processes is essential for seamless integration.

Research and Innovation:

Ongoing research and innovation in continuous pyrolysis technologies are vital for overcoming challenges and improving efficiency. Investment in research initiatives can unlock new opportunities and applications for the technology.

Conclusion:

Continuous pyrolysis stands at the intersection of waste management, renewable energy, and climate change mitigation. Its ability to convert diverse feedstocks into valuable products, while minimizing environmental impact, positions it as a key player in the transition to a more sustainable future. As technology advances and adoption increases, continuous pyrolysis has the potential to reshape waste management practices, contribute to renewable energy portfolios, and play a significant role in addressing the urgent challenges posed by climate change. By embracing this innovative approach, we pave the way for a more resilient and sustainable planet, where waste becomes a resource and climate action becomes a collective responsibility.