Convert Wood into Charcoal Efficiently

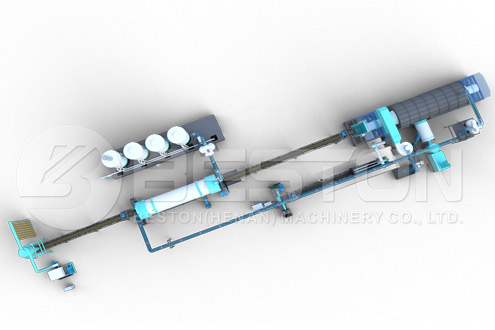

Charcoal can be obtained from wood or other biomass materials. Its raw material is burned under high temperatures to produce the carbon material (charcoal) which is used to produce energy. And we also need to know how the wood charcoal making machine works. The following is the process of turning wood into charcoal undergoes the following stages:

Drying of the wood

The wood is fed into the biomass carbonization machine where it first undergoes thorough drying where in many instances the drying is done more than once to remove any traces of moisture in the wood.

Pyrolysis process

This is the key thermochemical stage in charcoal production. The dried wood is exposed to extremely high temperatures ranging from 200-300 degrees Celsius while ensuring that there is no oxygen by covering the wood with soil or bricks to prevent it from completely burning. The core aim of this process is to get rid of liquid and gaseous components in the wood leaving the wood to be rich in carbon.

Cooling

The material from wood is passed through a water-cool conveyor to desulfurize the hot flue gas. The smoke and steam is later directed to the recycle water pool by the condenser.

End product

After drying, pyrolysis and the cooling processes, this final charcoal is obtained which is rich in carbon to upto 90% which is approximately twice the carbon content in coal.

Properties of charcoal

· Hard and brittle

· High amount of carbon of upto 90%

· Very minimal moisture content of about 5-15%

· It has a decolourisation component

Why you should consider using charcoal for energy production

·Charcoal is convenient for cooking as it produces no smoke while cooking thus rendering it user friendly.

·Due to its multiple small components, it provides adjustable heating capacity.

·Apart from providing energy, charcoal plays a key role the process of water purification as it decolorizes the water and gives it a natural taste.

·It saves on costs quite a great deal since it takes time before it burns down completely.

Significances of biomass carbonization plant

· This biomass carbonization plant impacts the environment positively as it produces carbon dioxide gas which is absorbed by the plants useful for photosynthesis with the aid of sunlight energy.

· This plant produces fossil fuel like oil and coal which plays a major role in energy production.

· Apart from charcoal production, this plant can also produce electricity as it contains 11,000MW renewable energy.

· Biomass carbonization plant also assists in environmental conservation since its by-product is from the waste products from living things which could pose negative impact to the environment through its emission.