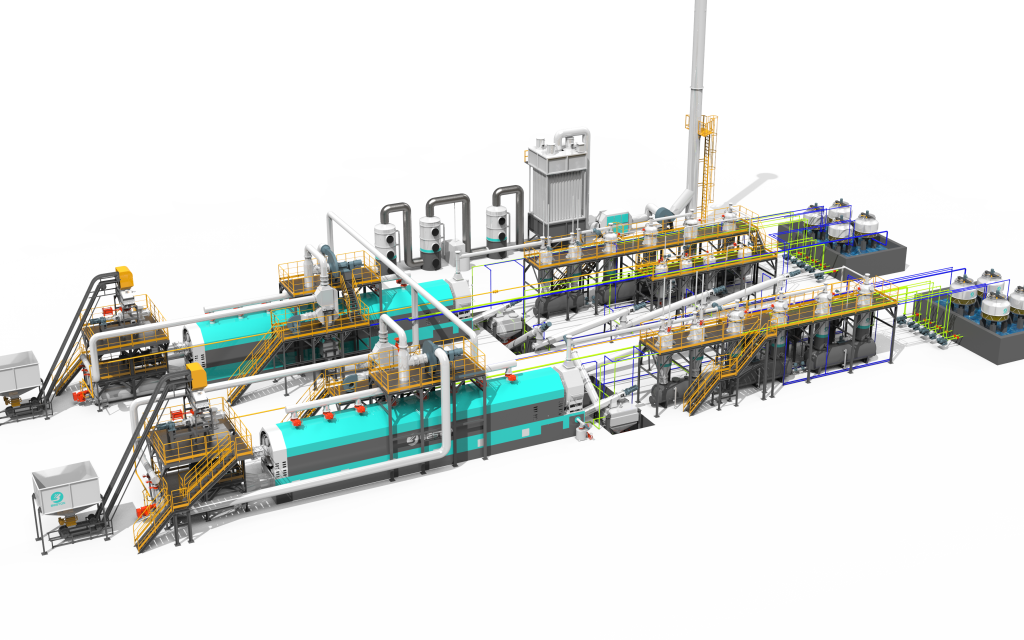

Exploring Feedstock Versatility: What Materials Can a Pyrolysis Plant Process?

A pyrolysis plant stands at the intersection of sustainable waste management and energy recovery. Its core function—thermochemical decomposition of organic materials in the absence of oxygen—makes it remarkably adaptable in terms of feedstock. As global industries seek circular solutions to manage waste and reduce reliance on fossil-derived fuels, the versatility of pyrolysis systems becomes a major advantage.

Waste Plastics: A Prime Candidate

One of the most prevalent inputs for a plastic pyrolysis plant is post-consumer plastic waste. Polyethylene (PE), polypropylene (PP), and polystyrene (PS) are especially suitable due to their high hydrocarbon content. These plastics, often difficult to recycle mechanically due to contamination or composite structure, can be transformed into pyrolysis oil, syngas, and char. The resulting oil serves as an alternative fuel or a base for re-refining into new chemical products.

PVC and PET, however, pose processing challenges due to the release of hazardous compounds during pyrolysis. Their inclusion requires pre-sorting or chemical scrubbing technologies, which adds complexity to the operation.

Oil Sludge and Drilling Waste

A thermal desorption unit, functionally aligned with pyrolysis principles, specializes in treating oil-contaminated materials like drilling mud, refinery sludge, and tank bottom waste. These feedstocks are complex emulsions containing water, hydrocarbons, and solids. When processed thermally, the volatile fractions are recovered as usable hydrocarbons, while inert solids are stabilized for disposal or further treatment.

The process is particularly valued in oilfield remediation, as it reduces hazardous waste volumes and enables partial resource recovery without incineration.

End-of-Life Tyres and Rubber Derivatives

The tyre pyrolysis plant segment has experienced notable growth as scrap tyres proliferate globally. Composed of natural rubber, synthetic rubber, carbon black, and steel, waste tyres yield valuable outputs including fuel oil, recovered carbon black, and steel wire. The high calorific value of rubber makes tyres particularly efficient in terms of energy recovery.

Whole tyres, shredded rubber, and even conveyor belts from industrial sources can be used as feedstock. However, preprocessing—such as steel bead removal or size reduction—is typically required to ensure uniform heating and consistent product quality.

Biomass and Agricultural Residues

Although less commonly associated with traditional pyrolysis plant, biomass feedstock such as coconut shells, rice husks, corn stalks, and sawdust is fully compatible with advanced systems. These materials, when pyrolyzed, produce biochar, a stable form of carbon that enhances soil fertility and serves as a carbon sink.

Moisture content must be controlled, ideally under 15%, to avoid energy inefficiency and incomplete carbonization. Some plants include drying units integrated into the thermal cycle to optimize this parameter.

Conclusion

Feedstock flexibility remains one of the most compelling advantages of pyrolysis technology. Whether in the form of a plastic pyrolysis plant, tyre pyrolysis plant, or thermal desorption unit, these systems are engineered to adapt. From agricultural waste to industrial sludge, the right configuration transforms problematic waste into economic and environmental value. This adaptability positions pyrolysis as a pivotal player in future-proof waste-to-energy infrastructure.