Outstanding Benefits Of Modern Rubber Pyrolysis Plants

Rubber is one of the most abundant materials that we have on the planet today. It is not just the result of growing it naturally. It is the result of the billions of tires that we have in landfills from vehicles that we drive. These can be from motor vehicles, airplanes, and a host of other sources. What is not known by most is that these rubber tires can be broken down into different components, all of which can be resold for a higher profit. It is also a great way to supplement the incredible amount of energy that we all consume on a daily basis. That is why rubber recycling plant is becoming more common and used by more businesses around the world. This brief overview of how they work will help you understand why this might be a good fit for your company.

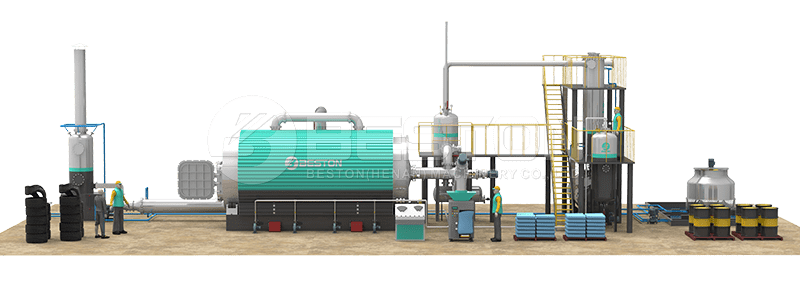

Inner Workings Of A Rubber Pyrolysis Plant

There are several different steps when it comes to converting rubber into usable fuel. The byproduct, both liquid and solid, only becomes this way through a breaking down of the original rubber material. For example, if you are in charge of some large landfill, most of which has rubber tires, you literally have an endless source of potential energy. The key is to use a pyrolysis plant that is not only efficient. The continuous pyrolysis plant is geared to work 24 hours a day. Doing so will produce thousands of gallons of usable fuel for many different motor vehicles. It will also produce solid materials, a byproduct of pyrolysis, and there will also be metal or steel that can be reused. This process begins with making different pieces of rubber into smaller components. This will then be heated and will be broken down so that the individual components can be extracted. More details about the pyrolysis process can be found: https://ecobeston.com/waste-pyrolysis-plant-for-sale/.

Does This Take Up A Large Amount Of Room?

This pyrolysis process doesn’t take a lot of time. Nor does it take very much room at all. At least, by comparison to a large landfill of tires, it is going to be minimal at your facility. It will require a conveyor belt system, a chipping machine for the tires, and a pyrolysis machine. Most larger establishments will have multiple pyrolysis machines functioning simultaneously to produce as much fuel as possible. It does also require multiple workers that can keep everything running, despite the fact that this process is almost fully automated. Once it has broken down the rubber, there will also need to be individuals that can contain, and subsequently deliver, the fuel to different distributors.

Are These Very Efficient?

These are certainly very efficient because of the major advancements that have been made for the last decade or more. They can produce more fuel, go through more rubber, and thus increase the bottom line for every business that is using them. The efficiency is often based upon the size of the components used, and the speed at which the rubber material can be moved to the proper temperature. Aside from that, it’s all about having as many of these as possible and operating them with high levels of efficiency. Beston Machinery is an experienced pyrolysis machine manufacturer, which can offer you pyrolysis oil plant project report. You can check the link here for more details: https://ecobeston.com/tyre-pyrolysis-plant-project-report/.

Where To Find Companies That Offer These

Locating businesses that offer there is a very simple process. Many major companies, especially in areas such as China will have multiple businesses producing them. These are often sold to different countries, and depending upon the size of the order, can be delivered all at once. This will include the pyrolysis reactors, conveyor systems, storage tanks, and everything else needed to ensure that this process is as fluid as possible.

A rubber pyrolysis plant can be obtained for a very minimal cost. The benefit of owning one or more of these will be seen after it. Just a few months. In fact, some companies are able to pay off their entire investment in a few years because of the high demand for these organically derived fuels. As more companies begin to modify or modulate the production of combustion machines for fuel, this will become a much more common way to power your vehicles. Be sure to compare different companies that sell pyrolysis plants that can produce rubber. By the end of the week, perhaps sooner, your order will be placed for one of these outstanding modern pyrolysis units that can produce biofuel from rubber products. Welcome to contact Beston Machinery for more details!