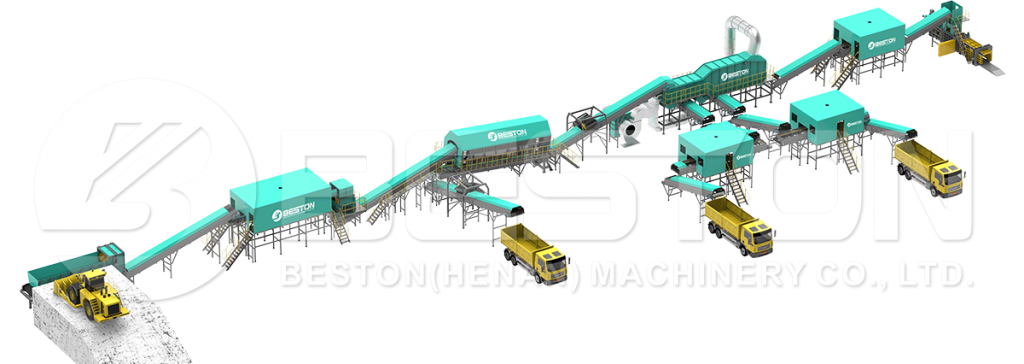

The working process of stone crusher uses a machine that is designed to crush large rocks into various sizes from small, to gravel, to dust. Stone crushing machines are also used to change the form or reduce the size of waste materials for recycling or for easier disposal. In the case of rock ore they are used to reduce a solid mix of raw materials into different compositions so that pieces can be differentiated.

The working process of stone crusher plant involves the transference of a force that is amplified by mechanical means on materials that resist transformation more and bond together stronger than those being crushed. The materials are held between two tangent or parallel solid surfaces while sufficient force is applied to bring both surfaces together which generates enough energy within the materials to separate its molecules (fracturing).

A stone crushing plant includes a jaw crusher, a cone crusher, an impact crusher and a mobile crusher. These machines are most commonly used in stone quarries and constructions sites to crush larger stones into smaller ones. Crushed stone can be used for a variety of purposes including the levelling of surfaces, to create gravel roads, and for drainage under buildings and roads. More about Aimix Group.

All crushers have a hopper which is a container that holds the larger pieces of rock and makes use of gravity to feed the rock into the crusher. Some crushers have a belt drive that continuously feeds the stone into the crusher. Once the stone has been crushed into smaller pieces they fall through a hole in the bottom of the crusher onto a conveyor belt or into a bin or a pile. Sometimes the crushed rock is fed into a second crushing machine to be crushed into finer pieces, or in even finer particles in three or more stages.

Jaw Crusher

The oldest and simplest of rock crushers is the jaw crushing plants for sale. The giant collapsible V shape consists of two metal walls that move the jaws with the help of a motor driven pulley. When the jaw moves up the angle between the jaw and the toggle plate increases, locking the jaw and crushing the stone in the process. When the angle between the jaw and the toggle plate decreases, the jaw is pulled away by a rod and spring and the crushed stone is dropped from the jaw.

Impact Crusher

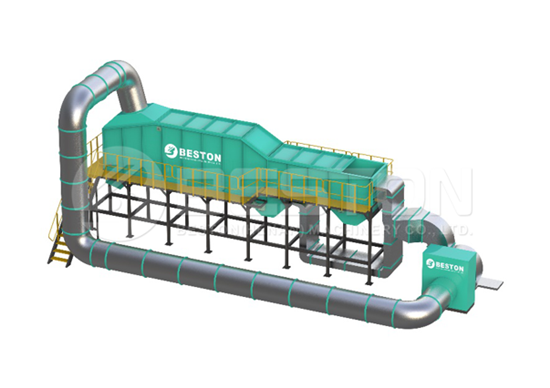

An impact crusher works by striking material with energy. A motor driven rotor rotates at high speed on which a blow bar is installed. The minute the rock gets into the blow bar area it is struck by the blow bar and discharged into the devices surrounding the rotor. The high speed of the rotor forces the rock to continually rebound from the impact liner back into the blow bar area until the stone has been crushed to the required size. The clearance between the rotor and the impact racks are adjusted to the required size and shape of the end products.

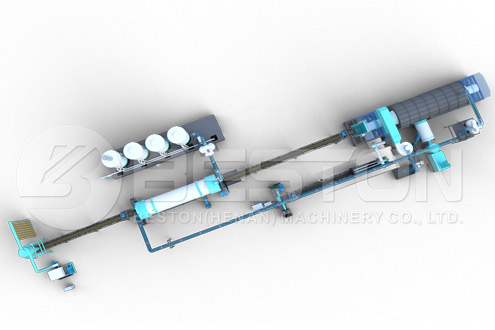

Cone and Gyratory Crushers

Although they are designed slightly differently, mobile cone crusher for sale work in much the same way as other crushers. In a cone crusher the rock is fed into the chamber from the top to fall into a spinning grinder located at the bottom of the chamber. As the stones fall down they are squeezed between the grinder and the walls of the chamber and crushed. The further they fall down the more they are pulverized into smaller particles until they are small enough to fall out of the bottom hole.