India is a country with an ever-growing economy. The tray-making business has rapidly grown over the last few years. The availability of many farmers rearing chicken for eggs has increased the demand for egg trays. The egg tray machine in India is a valuable commodity with the potential to scale business higher. There are large-scale and land small-scale investors in need of the devices. The demand has propelled the invention of varying types of egg tray machines in the region. A visit to the market will reveal the following types of machines.

Manual Model

Small businesses mostly utilize the manual egg tray machine in India. Its features cannot manage to meet the huge demand. The first step of production requires physical input to place the raw materials and mix them. The process also relies on manual input. The long-term effect of such production is huge losses in energy. Also, there is a likelihood of facing delays as the production relies on the energy capacity of your employees. The other vital part is the drying system. The machine employs natural drying models, which take place under the sun. The method is affordable but comes with lots of uncertainties. You have to check the weather forecast before embarking on any production. The ideal weather is when it’s sunny and windy. On such days you can take up around eight hours to sufficiently dry the egg trays. On cloudy days, the process can go on for days before achieving the goal. You might save some money during purchasing, but the risks for massive losses are huge with this option. Click here to know more: https://eggtraymakingmachine.net/.

Semi-Automatic Model

The second design under this category is the semi-automatic egg tray machine. This model’s functionality levels are much superior compared to the first option since it features automated machines that expedite its performance. Its production capacity is at least 8000 pieces of egg trays within an hour. It can suitably work in locations with medium demand without presenting delays. The drying line efficiently dries a large number of egg trays with a given period. Its construction is quite costly, but it’s a one-time investment. It requires minimal maintenance and is unlikely to present any problems. The purchasing price is quite higher, but it can optimally perform and bear the expected results through proper placement. More information on paper egg tray machine manufacturer here.

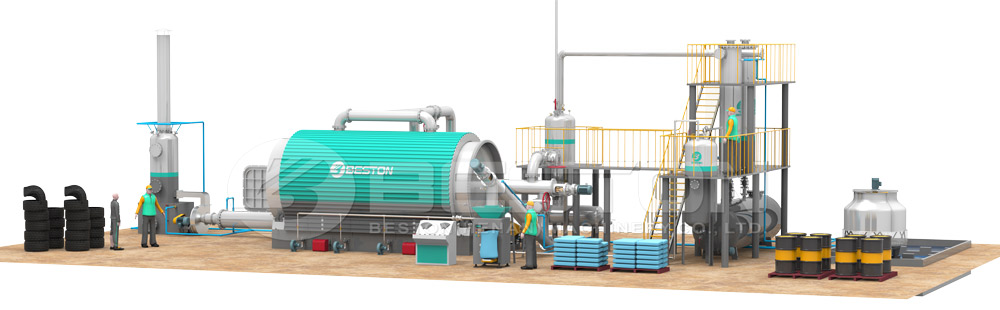

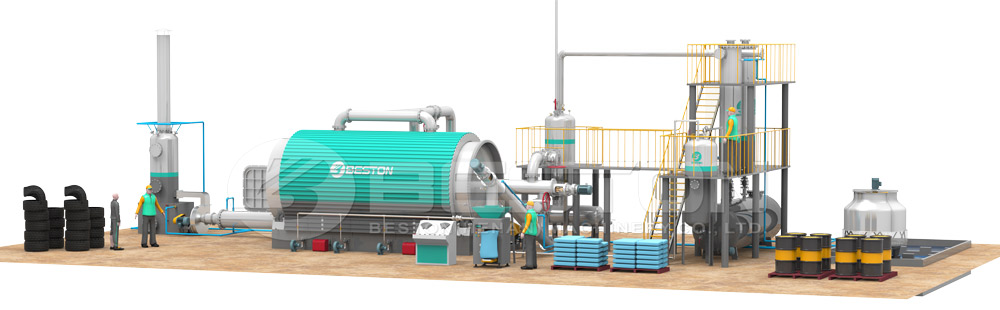

Automatic Model

Last but not least is the fully automatic egg tray machine In India. It’s quite costly, but the returns on investment for this model are worth it. The machine employs a fully automated system to produce the egg trays. The provision eliminates any chance of inaccuracies and delays. Furthermore, the drying system is a metallic structure with a conveyor to move the egg rays around. It consumes minimal energy and can operate on various fuel sources, including diesel, gas, and LPN. It might be costly upfront but has a huge potential of bringing in more profits for your business. It can deliver up to 12000 egg trays in an hour.

The detailed information on the different types of egg tray-making machines will help you make suitable decisions for your business. More information on Facebook: https://www.facebook.com/eggtraymakingmachineforsale.