When reading about biomass pyrolysis plants, you often see much information about waste plastic and waste tyres. Yet these machines can recycle more than just those two materials. They can recycle oil sludge, and much has been said recently about the recycling of biomass, which yields bio char, oil and four different gases. That’s a lot of byproduct just from recycling waste materials. Buy the biomass pyrolysis plant now.

You might be wondering if you have to use all the gas in house. It can certainly be used to power the reactor. What about the bio char? Does it have the same or similar uses as bio char? And you want to know about the bio oil, too. Is it the same as pyrolysis oil? The pyrolysis oil can be used to heat up the reactor on a pyrolysis machine. Go on bestonturkey.com/.

What you get from the pyrolysis machine when recycling biomass depends on the temperature achieved during the process. For example, with lower temperatures, you’re mainly going to yield bio char. Keep that in mind if that is your ultimate goal. You might want to look into what’s going to be more profitable for you. When you operate the pyrolysis plant at higher temperatures, you are mainly going to yield gases.

While there are four types of gases that you yield from biomass put through the pyrolysis process, you’re going to want to be sure that you understand what you’re missing out on if you yield mostly gases. That bio char is quite marketable, but again, it depends on your needs.

Are you buying a batch pyrolysis plant or a continuous pyrolysis plant? You could always run the machine at different temperature settings to yield whatever products are in high demand at the time. It’s up to you how you set up your recycling operation, but you’re set to do so if you invest in a biomass pyrolysis plant. Have you already started talking to manufacturers?

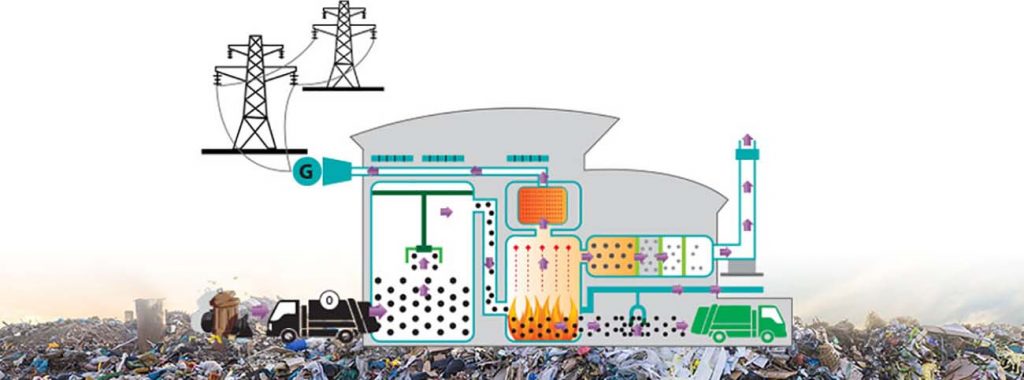

Maybe you have just now been looking into the idea after hearing that biomass could go through the pyrolysis process and net you a profit. What is going to be your impact on the environment? You’re going to want to know that as well. The pyrolysis process is a favored recycling method, especially when it comes to waste tires. But what about the plastics, biomass and oil sludge?

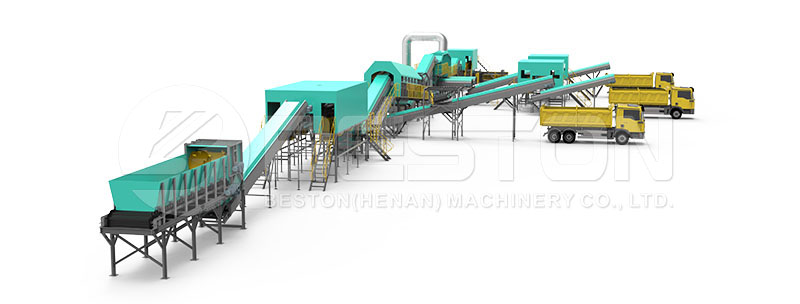

When speaking with manufacturers, ask them what sets their biomass pyrolysis plants apart from the plants available from other companies. Talk to them about the components of their machines. And to be sure, price is certainly a factor when you’re going to make this type of investment. Ultimately, you want a pyrolysis plant that is going to provide the results you’re looking for.