Pyrolysis Plant Feedstock Selection and Quality Standards

The efficiency and reliability of pyrolysis technology depend fundamentally on the quality and consistency of feedstock. Whether the objective is to generate liquid fuel, recover carbonaceous residue, or achieve environmental remediation, the choice of input materials dictates both yield and operational stability. From polymers to biomass and industrial byproducts, strict quality standards are essential for safe, efficient, and scalable pyrolysis applications.

Plastic-Derived Feedstock

In a waste plastic to oil machine, polymer selection directly affects output composition. Polyethylene (PE) and polypropylene (PP) are preferred for their high calorific value and predictable thermal decomposition, producing oil fractions with minimal impurities. Polystyrene (PS) contributes aromatic hydrocarbons useful for chemical recovery. Conversely, polyvinyl chloride (PVC) and polyethylene terephthalate (PET) are considered problematic. PVC releases corrosive hydrogen chloride during pyrolysis, while PET generates oxygenated compounds that complicate refining. Strict sorting and pre-treatment protocols therefore become indispensable for ensuring reactor longevity and oil quality.

Moisture content, contamination with metals, and residual coatings can degrade performance. Feedstock should be homogenized, shredded, and dried to a target moisture level below 15% to maintain reactor stability. Advanced pre-processing systems integrated within modern Beston Group pyrolysis solutions help operators achieve these standards with minimal manual intervention.

Tire-Derived Feedstock

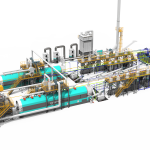

A waste tire pyrolysis plant is engineered to process discarded rubber products, transforming them into pyrolysis oil, carbon black, and steel wire. The ideal feedstock is composed of whole or shredded passenger and truck tires free of excessive mud, stones, and embedded debris. Uniformity in size and composition enhances heat transfer within the reactor, improving throughput efficiency.

Quality standards often require testing for halogenated additives or excessive sulfur, as these can lead to secondary emissions or complicate downstream oil upgrading. Pre-processing, including de-beading and cleaning, reduces risks of equipment wear and maintains product quality at an industrial scale.

Contaminated Soil and Industrial Residues

For remediation-focused operations, a tdu thermal desorption unit provides a viable pathway for treating hydrocarbon-contaminated soils, drill cuttings, and industrial sludge. Feedstock quality assessments must account for hydrocarbon concentration, particle size, and moisture level. Excess water content slows the desorption process, demanding additional energy input. Standards often mandate laboratory analysis before acceptance, ensuring that the material is suitable for processing without exceeding emissions limits.

The integration of monitoring systems is critical in these units, guaranteeing that volatile organic compounds and residual hydrocarbons meet environmental discharge regulations. A properly configured system not only recovers usable oil fractions but also ensures compliance with stringent soil remediation guidelines.

Importance of Quality Standards

The adherence to feedstock quality standards reduces risks of reactor fouling, improves oil yield, and prolongs equipment life. Uniform feedstock allows precise control over temperature gradients and residence times, leading to predictable product distribution. Without such standards, even the most advanced equipment is prone to operational inefficiencies.

Conclusion

Feedstock selection and quality assurance form the backbone of successful pyrolysis operations. In a waste plastic to oil machine, sorting polymers guarantees high-grade fuel recovery. In a waste tire pyrolysis plant, pre-processing ensures consistent performance. For soil treatment, a tdu thermal desorption unit relies on careful assessment to remain compliant. By enforcing stringent quality standards and leveraging engineered systems such as those from Beston Group pyrolysis technology, operators secure both environmental responsibility and economic efficiency in waste-to-resource conversion.