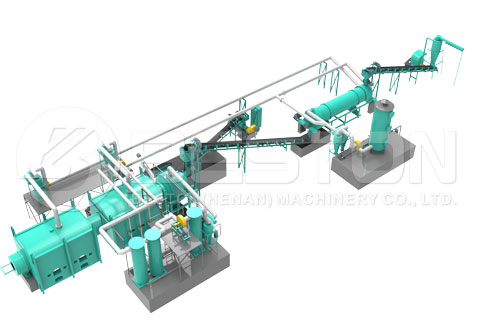

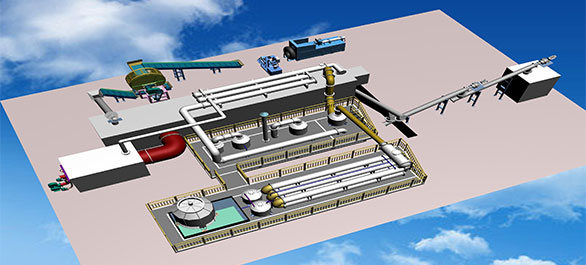

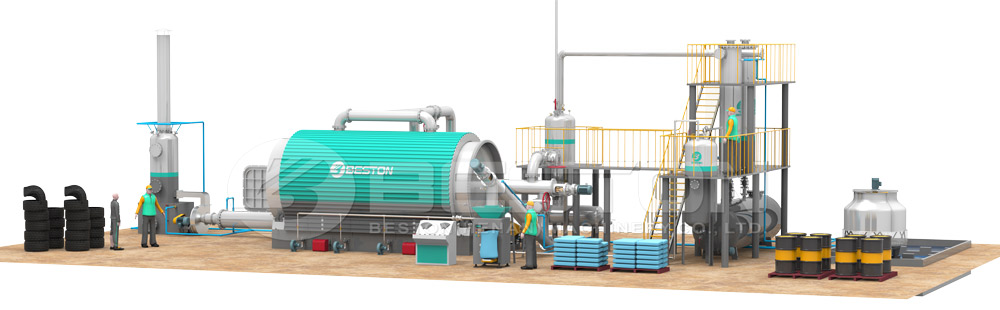

Are you shopping for a pyrolysis plant UK? If so, you have come to the right place. A tire pyrolysis plant is one of the most effective ways of taking waste biomass out of your environment. The plant uses various waste materials including rubber tires and heats them to a high temperature where they change into fuel oil, charcoal, carbon black, and steel wire. These materials have a high demand in the industrial sector and could be sold at a higher price. A pyrolysis plant is a strong investment where you could recoup your investment quite fast. Here is why you need to invest in a tire pyrolysis plant UK.

Millions of waste tires are collected in landfills across the United Kingdom each year. They do untold damage to the environment. Recycling old tires is one of the best ways to save the environment while making a profit by selling the byproducts of the recycling process. That is where a tire pyrolysis plant comes in handy.

A quality pyrolysis plant is quite economical to operate since it doesn’t amount to a large amount of money in operational costs. The unit is designed to use as little energy as possible and work continuously to provide you with profitable end products. The pyrolysis machine for sale won’t produce much pollution and is extremely safe to operate in any warehouse or facility. It is an ideal investment for anyone who wants to earn extra money and save the environment at the same time.

There are many important factors to consider when investing in a quality pyrolysis plant in the UK. The manufacturer, his reputation, experience, and customer feedback are some of the most important factors to look for. The potential manufacturer or supplier should have a good reputation in your community. They should have the necessary experience in designing high-quality pyrolysis plants for the UK market. The internet is one of the best places to find reputable pyrolysis plant manufacturers in the United Kingdom. You will come across the host of manufacturers or suppliers in the country by performing a simple search on Google or any other search engine. Many clients make the mistake of going with the first manufacturer they come across Google SERPs. You need to check the background of each manufacturer before choosing the best pyrolysis plant manufacturer to purchase the small scale pyrolysis unit.

The aforementioned article provides information on why you need to invest in a tire pyrolysis plant UK.