If you are in the city, and you are responsible for processing solid waste, you should consider investing in new waste sorting equipment. Yours might be outdated, or perhaps you are primarily using manual labor to do most of the sorting. There could be many things that you are missing. Some of these machines are able to extract significant amounts of recyclable material that can be resold for a solid profit. If you are able to do this, you should have no problem at all getting all of your money back from your investment because of how efficiently you will sort through all of that material. You will first want to evaluate the companies that sell these products, and then look at what they have in stock. Finally, you will make your choice by comparing a list of solid waste sorting equipment price to make your final purchase.

How Do These Machines Work?

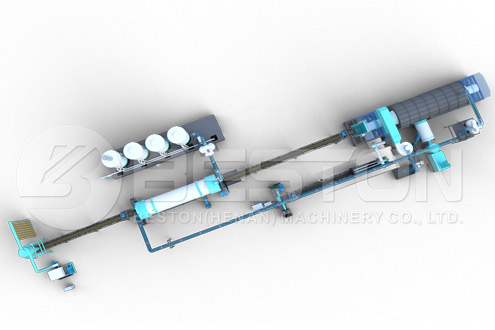

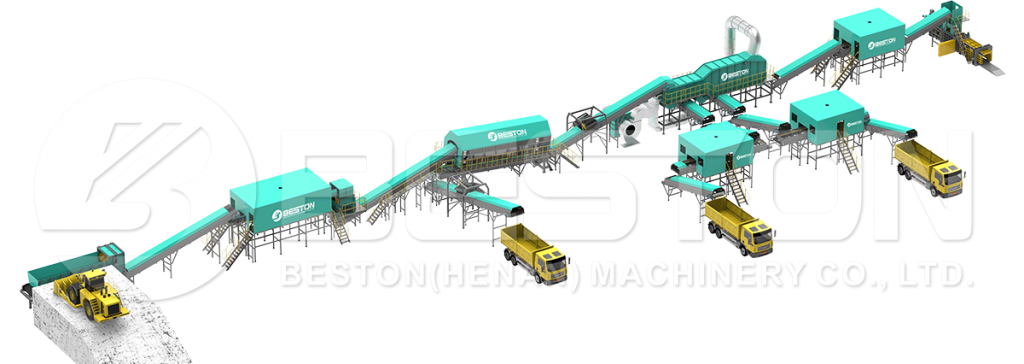

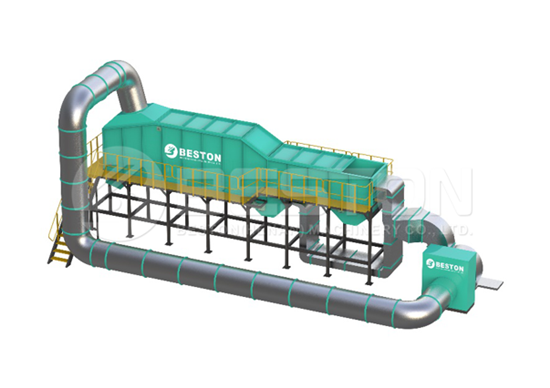

These waste recycling systems work in a very systematic fashion. They are designed to work in tandem with the workers that you employ. There will be garbage trucks that will bring in the material that is to be sorted. This will then be put onto a discharge platform, sorted by hand, and then the rest will be moved onto a conveyor belt. By this time, it is becoming uniformly distributed. This will make it easier for the rest of the process to occur. Your apparatus may include a rotating screening machine, plate feeder, or a comprehensive winnowing machine, all of which are working together to sort as much of the debris as possible. More details can be found: https://bestonasia.com/garbage-separation-system/.

Where Should You Start Looking For The Garbage Sorting Machine?

Most of these sorting machines can be located by searching on websites that have advertisements from businesses like this all over the world. You will get to see their websites, how much they are charging for the different products they have available, and finally, you can compare the capabilities of each one. You are going to choose one based upon what it can do, and the prices that they charge. Also, consider how long it will take to arrive at your location. It may take you a few days to get estimates back from different companies that you are requesting prices from, but in the end, you will know which one you will want to choose.

Will This Work With Any Type Of Solid Waste?

This will definitely work with most forms of solid waste that originate from the city. For example, most of your garbage will probably come from residential homes, apartments, offices, schools, restaurants, and hotels. Most of this garbage is going to be very similar such as food, solid materials like plastic and metal, and miscellaneous items that can be physically pulled out. Everything else should be sorted by the machine either through magnetism or through the conveyor system that has screens that can separate the debris based upon its size. All of this is going to work automatically, and with the exception of your workers that will sort through the material initially, the automatic waste sorter will do the entire job.

The material that is sorted can then be distributed appropriately. The garbage that cannot be recycled will be taken to a landfill in most cases. That which can be recycled will be sold to people that can use this material. While some can be further processed, for example, you can make egg trays from waste paper with a pulp molding machine. That’s why investing in one of these units is so important because it actually gives you additional revenue by thoroughly sorting the solid waste. Prices that are not listed can be provided to you by the actual owners of the solid waste sorting equipment, helping you to make your final choice.