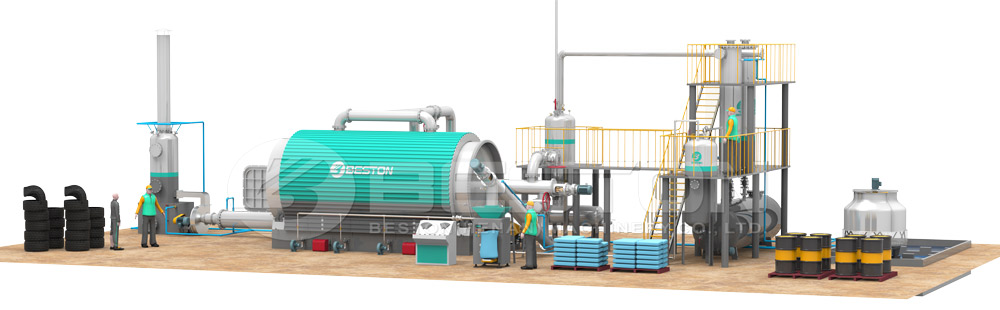

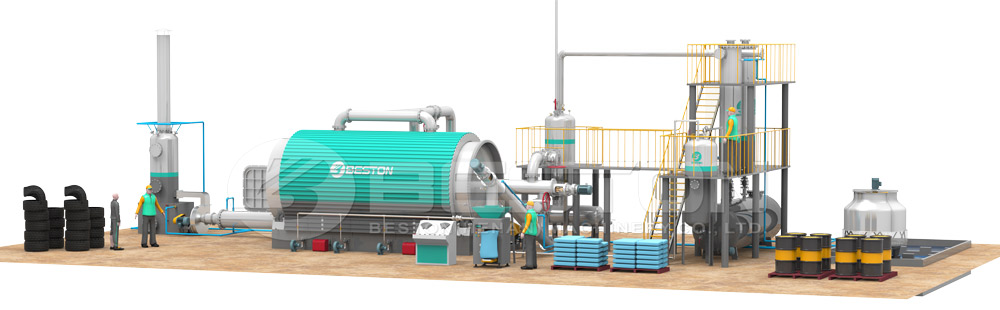

If you have waste wood that you want to to turn into something useful you need to make sure that you choose a wood pyrolysis plant to help you get things done. This plant can help you in many ways and it is just what you need to invest in when you want to make a lot of money. You just can’t go wrong with this wood chips charcoal making machine.

This machine can help you get a lot of work done and it is very easy to use. The machine has a lot of benefits for your business and it helps you take care of your needs with ease. It uses any type of scrap wood and heats it up to a very high temperature where it is turned into charcoal.

The charcoal is used across a wide variety of industries. The charcoal is used to heat things and burn things. It is also used for incense and is a raw material in many types of things. This machine produces charcoal that is high quality and the charcoal can be used in so many ways.

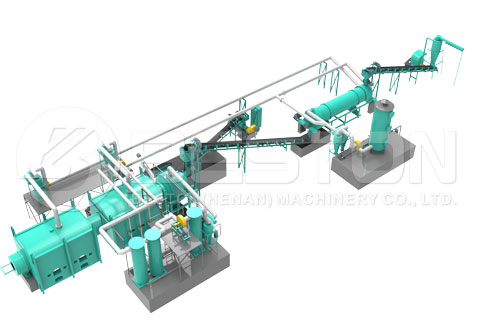

Choosing the right charcoal processing machine can be an issue which means you need to think about doing a lot of research so you learn all about the different kinds of machines. You want to learn everything you can about these machines so you have all of your needs taken care of. These machines are a great deal and you can get so much done with them.

One of the great things about investing in a wood pyrolysis machine is that the manufacturer is going to install the machine for you. You won’t have to deal with the installation yourself since they handle the entire process. Not only will they set everything up they will also provide training so you know how to use the machine. They provide quality training and ensure that you and your workers know how to safely operate the machine.

You save a lot of time and money when you let the biochar pyrolysis machine manufacturer help you. Their free training and installation saves you thousands. You also get free technical support for as long as you own the machine which means that you get the free training whenever you need it. This plant can be very easy to use and it is a great investment.

When you are ready to make big profits and produce tons of charcoal invest in one of these machines. They are a great deal and they help you a lot. You get to make money fast with them.