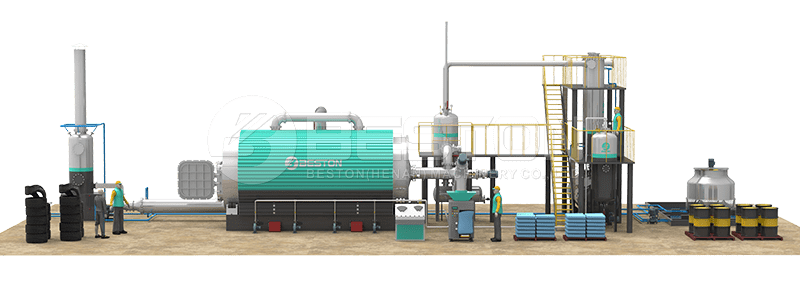

Making a profit with any business can be difficult to do. If this is your first time in the tire recycling business, you may not understand how to make a solid profit. Part of that strategy involves having state-of-the-art oil sludge pyrolysis plant that can convert the rubber into a burnable fuel. The other is to have an ample supply of recycling materials such as rubber tires from a landfill. You may also be an individual that is responsible for the municipal solid waste coming out of your city. There will likely be thousands of tires at your disposal. If you want to make a fast profit, and a consistent profit from day one, here is how you need to set up your tire recycling business.

How To Begin This Type Of Business

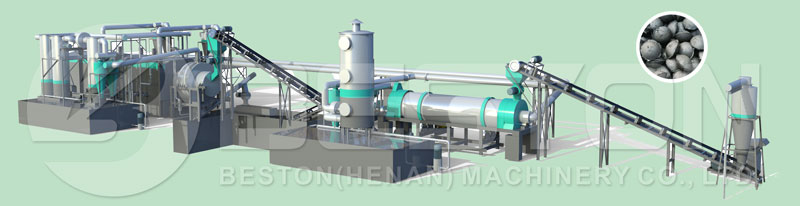

This business requires you to obtain a pyrolysis machine. If it is a large number of tires that you will be processing, a continuous pyrolysis plant will be the best choice. Both of these machines can be obtained from many companies that specialize in the conversion of waste materials into burnable fuels like bio-oil. Carbon black is also a byproduct of this process which can be extremely profitable. That is because there is a large demand for this type of material. If you are ready to obtain a profit the first week that you set everything up, you must first choose the best pyrolysis plant or machine that is available. If you want to know more cost details, please check the website here: https://bestonasia.com/tire-pyrolysis-plant-cost/.

Why You Should Get A Pyrolysis Plant

This type of pyrolysis plant is designed to process a multitude of different materials. You could start with the rubber tires that you have, and subsequently, expand into other materials such as plastic bottles. There are literally billions of plastic containers that are thrown out every year, many of which are going to end up in a landfill. You should get a piece of pyrolysis equipment if you are thinking about making the largest amount of profit. This will require you to have a consistent and large supply of materials to use.

Why The Tire Recycling Business Is Profitable

This is one of the more profitable businesses for a couple of different reasons. First of all, there is never going to be a time where rubber tires are not available. People are consistently rotating the ones they are using for new ones. The new ones are either disposed of at a local municipal solid waste facility, and varied, or they can be recycled for use with the pyrolysis apparatus.

It is the sheer volume of rubber tires that are produced worldwide that make this type of recycling business so profitable. Beston Henan Machinery is professional in this industry. As long as you have chosen the right pyrolysis plant, you should have no problem generating a profit in your first week. It is even conceivable that in the first few days of full operation, you may have buyers waiting to obtain your biofuel and any of the bio oil that you are able to produce. It is best to set these contracts up before you begin. Once you start, you can begin to receive money from these happy buyers that will be more than willing to take all of the byproducts of your tire recycling business.